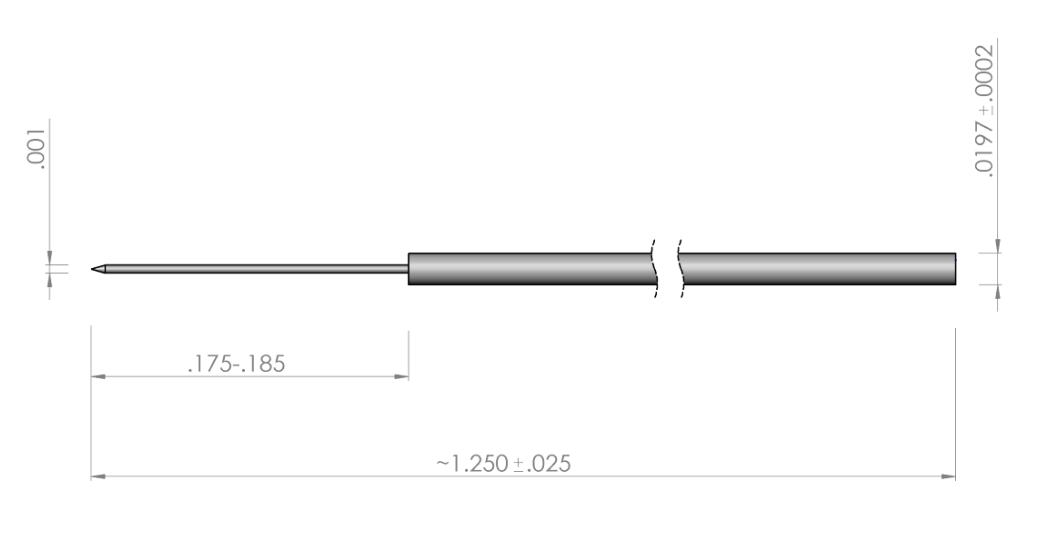

The 72F Series probes are constructed from a 1 mil (.001") tungsten wire crimped into a 20 mil nickel plated copper shank.

Features

Excellent for fragile In-Circuit probing.

Used for thermal and high vibration applications.

Specifications

Allows testing in high vibration applications.

1 mil wire will not damage fragile circuits.

Probe is designed to allow flexing of tungsten (over driving) without damaging radius.

Best used where there is a node or via that allows an anchor for the tip.

Note

The tungsten has a standard length of .195" from the nickel-plated copper tube.

A shorter tungsten length will offer a stiffer contact point.

All prices are EACH PROBE, NOT PER BOX

Sold in boxes of 10, 20, or 25.

This probe is also known as a 72FS when ordered with a shorter shank length. Specify this in the ordering options.

Made to order.

See also 72X

-

What size probe should I use?

-

The typical recommendation is to use a probe diameter that is half to two thirds the size of the contact. Remember, APT's probes are sold by the radius, so you must double the number to determine the diameter. It is normally found that a radius larger than 20 microns does not yield lower contact resistance. An example is: The contact pad is 10 microns, using the recommendation, you would then use a probe with a radius of 2.5 - 3.5 microns. (5- 7 micron diameter)

-

Why are some probes etch and others ground?

-

There are two common ways to manufacture the probe's taper and radius: 1.Electrochemically etch 2.Mechanically grind Why is one method chosen over another? 1.The base material is the driving reason: a. Tungsten, Tungsten rhenium are typically electrochemically etched b. Paliney® 7, beryllium copper, tungsten carbide, steel are generally mechanically ground materials This is the short answer, for more details on the subject please refer to the link in the Technical Resources Area under Probe Question's.

Dimensions of the 72F Series 1 mil (0.001") tungsten wire crimped into a nickel plated copper 20 mil (0.0197") shank.

The tungsten wire "contact probe" is electrochemically etched to form the taper and radius:

This probe offers the ability to flex with the adjusting contact point.

Applications:

- Thermal analysis, allows for vertical movement associated with this type of probing

- Probing in high vibration environments

- Probing delicate device structures for reduced contact damage

- Tungsten lengths can be ordered in longer or shorter lengths to customize probes physical characteristic’s

Please refer to this section for American Probe & Technologies cross reference to other manufactures model numbers.

Cascade Part Number |

Equivalent APT Model Number |

| 47165 | 72F-B5/075 |

Probing Solutions Part Number |

Equivalent APT Model Number |

| 407F |

72F-B3/05 x 1.25

|